Candy Twist Film

Material:Plastic Film

With the advancement of science and technology and the continuous improvement of people's requirements for material performance, functional textiles have gradually become the new favorite of the market. Among them, aluminum foil coated fabrics are widely used in aerospace, fire rescue, industrial protection, building insulation and other fields due to their excellent heat insulation, radiation protection, waterproof and wear resistance.

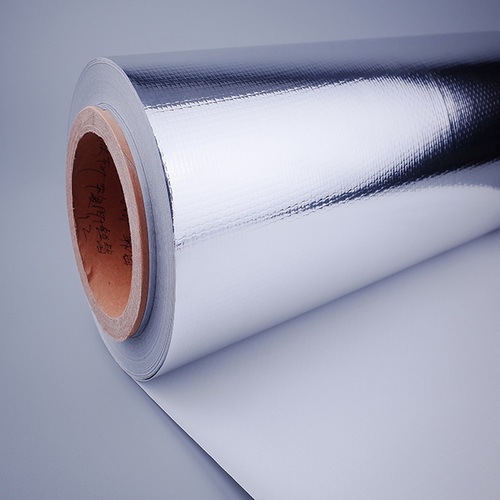

Aluminum foil coated fabrics are functional composite materials made of high-strength fabrics (such as glass fiber cloth, polyester fiber or Oxford cloth, etc.) as the base material, and a layer of high-purity aluminum foil or aluminum-containing composite materials is coated on the surface. This structure not only retains the flexibility and processability of the fabric, but also gives it the reflectivity, thermal conductivity and shielding properties of metal materials. It is a typical high-performance composite material.

Excellent thermal insulation performance

Aluminum foil has extremely high infrared reflectivity and can effectively block the transfer of external heat. Therefore, aluminum foil coated fabrics are widely used in building insulation, high-temperature workshop protection, car sunshades and other fields.

Electromagnetic shielding function

Electromagnetic shielding function

With the increasing popularity of electronic equipment, the problem of electromagnetic interference is becoming increasingly prominent. Aluminum foil coated fabrics have good electromagnetic shielding properties and can be used to manufacture shielding tents, communication equipment protective covers and other products.

Fire retardant ability

Most aluminum foil coated fabrics use high temperature resistant substrates and are processed through special processes to have good fire retardant properties. They are suitable for fire suits, thermal insulation blankets, high temperature filter materials and other scenarios.

Lightweight and durable

Compared with traditional metal plate materials, aluminum foil coated fabrics are lighter, easier to transport and construct, and have a longer service life and strong tear resistance.

In the aerospace field, aluminum foil coated fabrics are used to manufacture satellite insulation layers and outer protective covers of spacecraft to resist extreme temperatures and cosmic radiation; in the firefighting industry, it is widely used to make thermal insulation suits, escape blankets and other equipment to improve the survival rate of personnel in fire environments; in industrial manufacturing, this material is often used for high temperature pipe wrapping, boiler insulation, welding spark isolation and other purposes.

In the civilian market, aluminum foil coated fabrics have also been developed into a variety of innovative uses, such as reflective insulation car covers for cars, outdoor camping insulation pads, constant temperature sleeping bags, etc., to meet consumers' needs for comfort and energy saving.

With the development of smart wearable technology, future aluminum foil coated fabrics may integrate more functions, such as conductivity, sensing, etc., to promote the realization of "smart clothing". At the same time, the research and development of environmentally friendly coating materials will also become a key direction of the industry to reduce the impact on the environment.

As a new composite material that combines the advantages of metal and textiles, aluminum foil coated fabrics are constantly breaking through the performance boundaries of traditional materials. Its wide application in many fields not only improves the functionality of the products, but also brings higher safety and efficiency to related industries. In the future, with the further development of materials science, aluminum foil coated fabrics will show greater potential and value in more high-tech and livelihood fields.