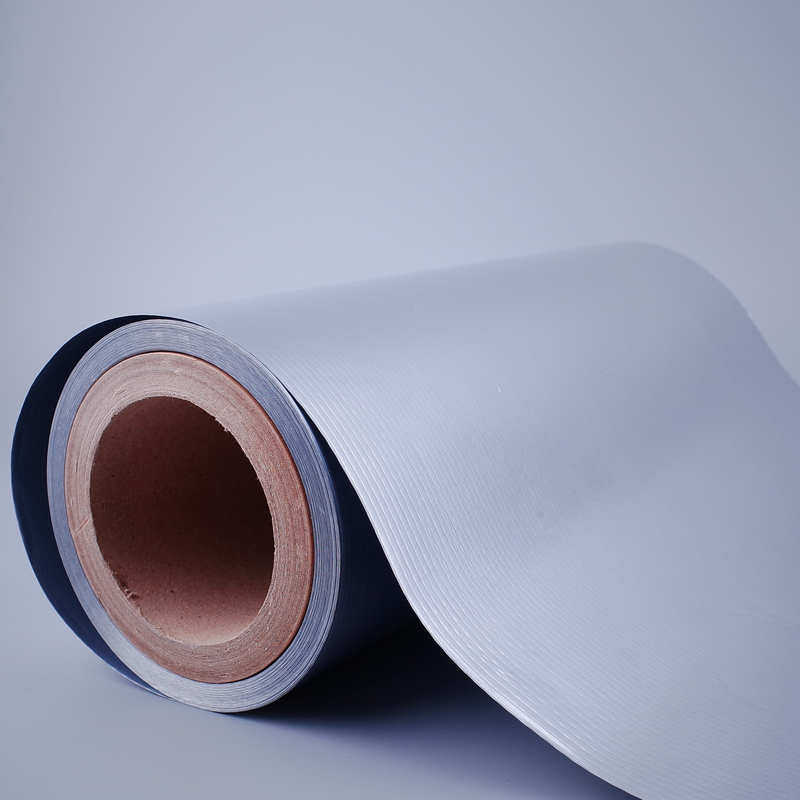

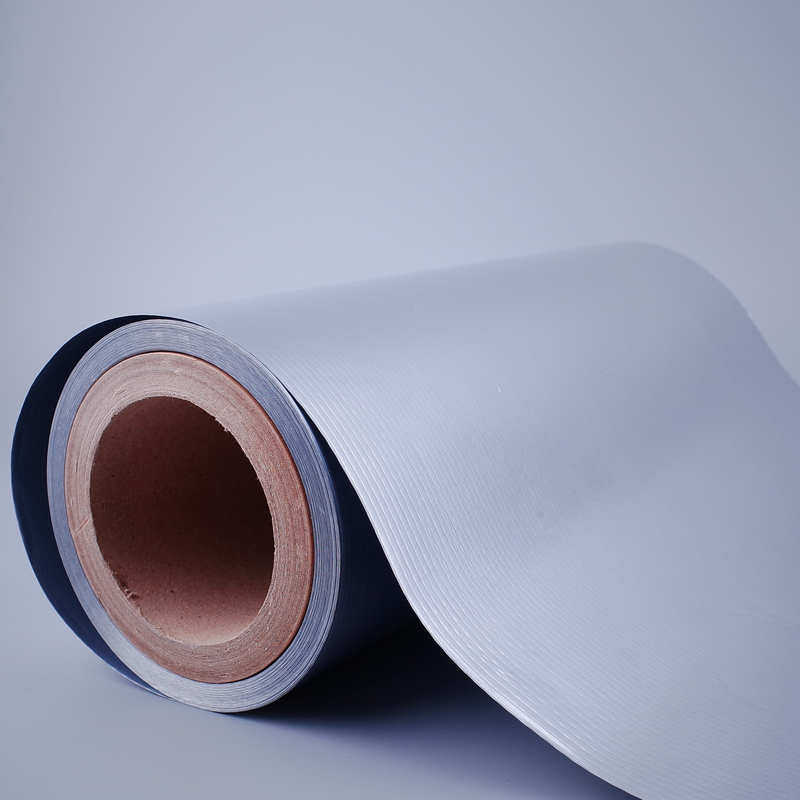

Mylar is a clear, thin

plastic film that can be used in many ways. It is often made with a layer of aluminum metal (less than 1/100th the thickness of a human hair in some cases), which gives it its shiny appearance. The film is also available in matte finishes and in a variety of colors. It is an excellent choice for projects that require a durable material that resists chemicals and moisture, or that need to provide a barrier against gases like oxygen.

The material is also useful for abrasion resistance and can withstand high temperatures. Mylar is a good choice for use in a variety of industries, including the packaging, manufacturing, aerospace, and medical sectors.

A common use for Mylar is in the production of packaging bags, such as coffee foil pouches and lids for yogurt containers. It offers a superior barrier to moisture and oxygen than aluminum foil, making it ideal for packaging pharmaceuticals, tissue samples, seeds, and other sensitive products. It can also be bonded to aluminum to create a stronger, more flexible packaging material.

Another popular use for Mylar is in the fabrication of stencils. The smooth surface of the film allows it to be easily cut with lasers or other cutting tools, and its low vaporization temperature means that Mylar can be used by even entry-level laser cutters. This makes the process very cost-effective, and it is a great way to create intricate designs or shapes that would otherwise be difficult or impossible to make with other materials.

Mylar is also commonly used to protect documents, and it can offer a significant increase in shelf life over standard paper. The material is impermeable to acids and oils, so it resists moisture well. It is also extremely strong, and can withstand abrasions. This is why the US Library of Congress uses Mylar to preserve important documents.

Mylar can be printed on using screen printing, doming, or digital printing, and it can be engraved. The surface of the film can be treated to improve its durability and adhesion, or it can be laminated for additional protection. Mylar can also be coated with UL-approved labels, which are commonly found on electrical appliances and controls, standing light fixtures, and other equipment.