A common finishing service, lamination is essential for a variety of applications including posters, signs, and presentations. It can also help add a glossy shine and stiffness to papers, cards, booklets, envelopes, and more. While it is often seen as a utilitarian step in the printing process, with a little cross market ingenuity, lamination can be used to elevate a range of products to stand out from the competition and make them more memorable to consumers.

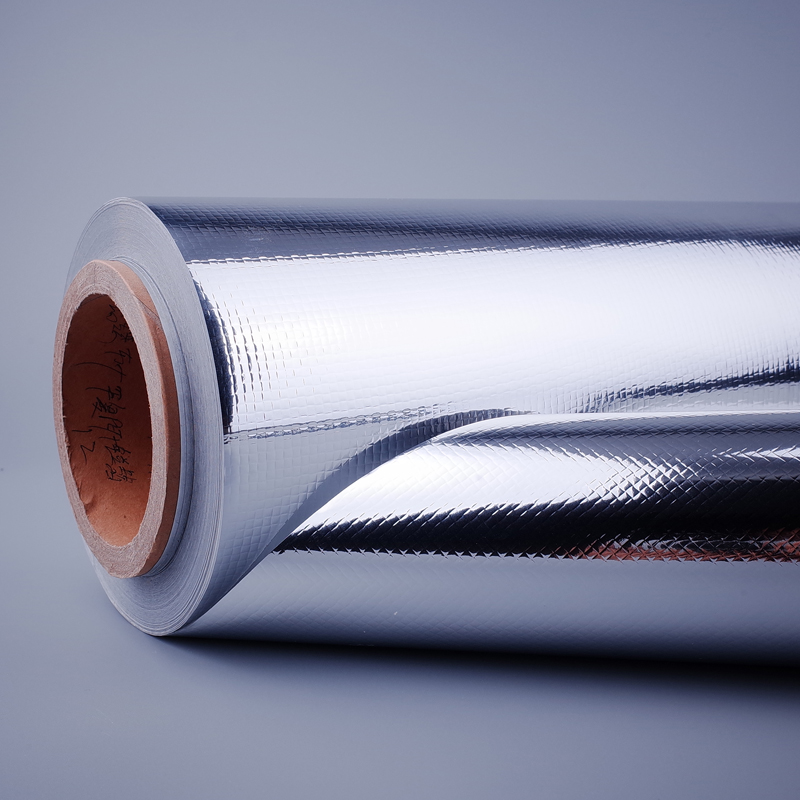

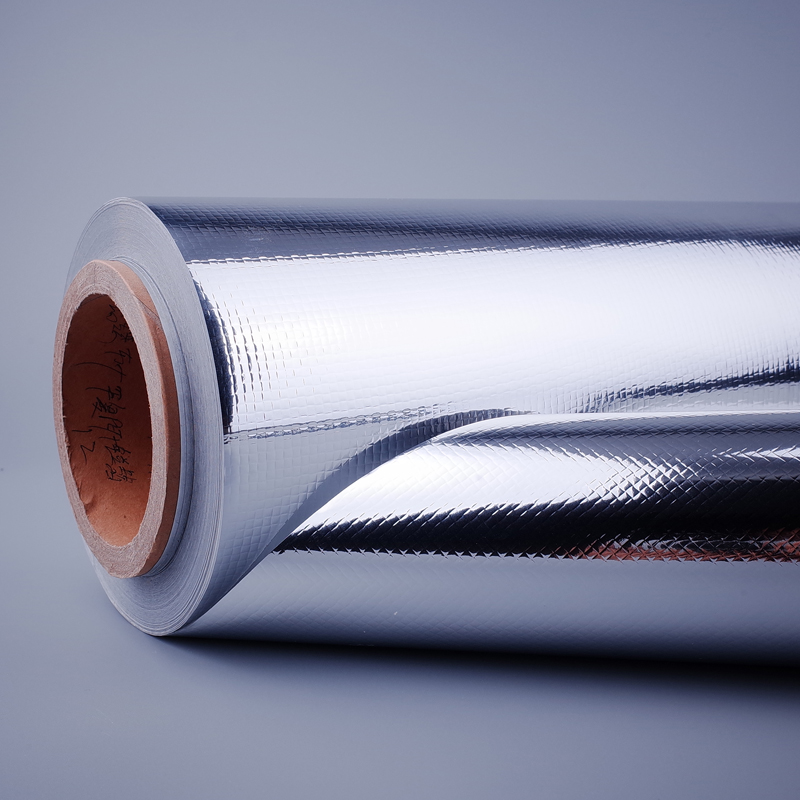

There are numerous types of lamination film available, each with its own special properties that influence the end product. From cost, equipment and application compatibility, receptiveness to post-laminate processes and more, each laminate is different. Regardless of thickness, finish or adhesive type, one factor that is common to all types of thermal laminating film is its base material.

Laminating films are usually made out of various plastics. There is usually a harder layer on the outside and a softer inner layer, or sometimes a combination of both. Polyethylene Terephthalate (PET) and Ethylene-Vinyl Acetate (EVA) are some of the most popular plastics to be found in laminate film. They are able to provide toughness and rigidity to the finished product, while at the same time being relatively lightweight for ease of handling.

The thickness of a laminating film is measured in “mil,” which refers to the amount of plastic and adhesive used within a single sheet. There is a wide range of mils to choose from, with thicker film providing more rigidity and protection. There are even anti-bacterial films designed for use with frequently handled materials in hospitals, schools, and other institutions to ensure safety and cleanliness.

Choosing the correct laminate thickness for a job is important as it can significantly impact how flexible or rigid the finished product will be, as well as its cost. It is also necessary to consider the environment, as some laminates may be exposed to direct sunlight or chemicals, which can require special qualities in the film such as UV-resistance.

In addition to choosing a film based on its plastic composition, it is also important to choose the right adhesive for the job. There are two main kinds of adhesives that are commonly used in the laminating industry, cold and heat-assist. Cold adhesives are pressure-sensitive and can be used over media that is not heat-sensitive, such as paper or fabric. Heat-assist adhesives are heated by the rollers in a laminator and are used over media that is heat-sensitive, such as vinyl.

Once a person has chosen the type of laminating film that they need, they can then select the specifics, such as size and adhesive type. Choosing the right size of film is crucial, as it must be compatible with the laminating machine that will be used. Usually, the width of the machine will be stated on the packaging or in the user manual. It is also important to choose a laminating film that is the proper size for the project, as this will ensure that it can be easily cut and folded if needed.