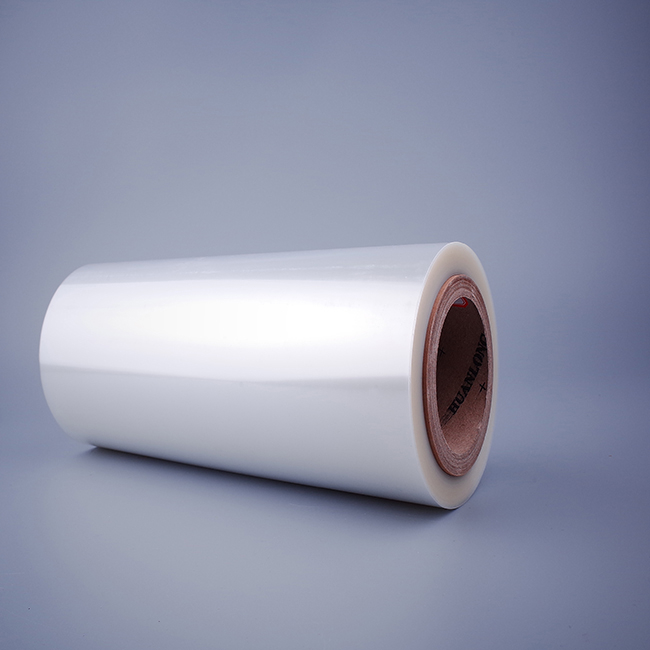

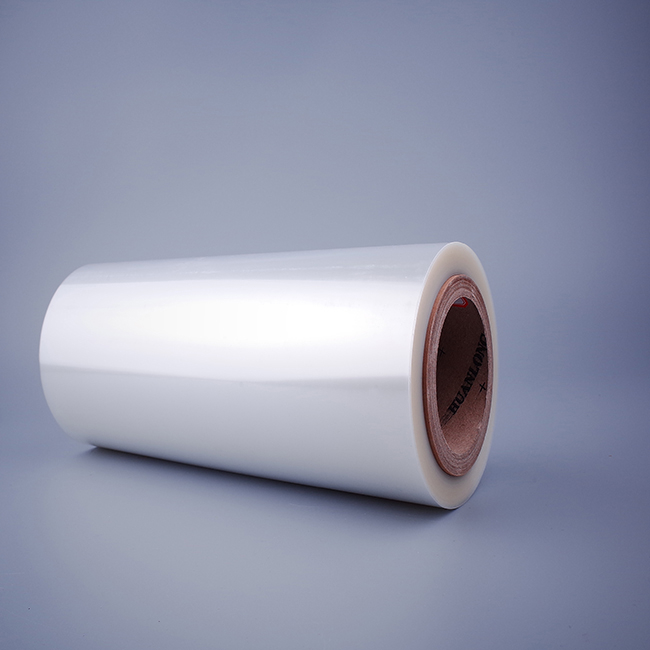

The packaging industry has changed so much in the past decade that now when we think of packaging, the first thing that comes to mind is flexible, easy-to-carry plastic bags; not metal/glass containers. Flexible packaging has become one of the fastest growing packaging solutions in the industry. While these have gone through many changes and improvements, one of the biggest innovations is its contribution to the food industry in the form of BOPP plastic films. These plastic films are widely used in the FMCG sector as they provide multiple barriers against external factors, keeping the interior intact and fresh for an extended period of time.

Moisture-proof, gas-proof, chemical-proof

Products such as pharmaceuticals, food, or cosmetics are susceptible to damage from moisture, chemicals, or outside gases, including oxygen. Here's how plastic film protects these products from damage:

These are well known for using polypropylene materials, especially for their good chemical resistance.

These films also have high sealing strength, preventing atmospheric gases such as moisture and oxygen from entering and destroying the contents inside.

Typically, BOPP plastic films have a density close to 0.90 g/m, thus offering higher yields at similar costs and being extremely cost-effective compared to polyester films.

Contrary to popular belief, BOPP plastic film promotes recycling and reuse (bags with zippers or spouts). These films can be recycled multiple times at low cost. Also, less power is consumed during manufacture.

prevent food waste

According to a report by the Food and Agriculture Organization of the United Nations, poor quality packaging is responsible for 50% of food waste worldwide. That's because, from farm to plate, exposure to oxygen or atmospheric moisture can cause adverse reactions. BOPP plastic film acts to protect chemicals, moisture and gases, greatly reducing the chance of food spoilage. Also, it keeps the internal aroma intact and food stays fresh longer. For these reasons, many food production companies have now turned to BOPP plastic films, which have undoubtedly proven to be very beneficial in the food industry.

Packaging Design Innovation and Customization

These can be molded into any shape and form, including lay-flat or stand-up bags.

It has excellent print quality and enhances the final look of the product through its glossy appearance.

Polyester film has a wide range of uses. Below we provide information on common applications for polyester films and why polyester should be used on other types of

metallized film manufacturer films.

Printed Electronics: Mylar is thermally stabilized at 150°C for 30 minutes (MD/TD shrinkage <1%) to ensure proper positioning and performance of the silver conductive ink.

Optical Displays: These devices require high-definition films, one side of which is pretreated to enhance adhesion to most printing inks and industrial coatings. Rely on polyester film for double-sided coating.

Flexible Electronics: Mylar can be used as printed shorting pads and bottom circuits in flexible electronics applications, including membrane switch circuits.

Medical Films: Applications for medical films include diagnostic test strips, transdermal patch assemblies, medical face shields, microfluidic testing, and medical labels.

Casting and Release: The action of "release" can be accomplished by adding a chemical coating (i.e. silicone), the most common type of product film is called: a mechanical process by adding fillers to the base polymer package.

Labels and Labels: Many products in Mylar can be used as a print-receptive base for pressure-sensitive labels.

Electrical Components: Mylar has high dielectric strength, heat resistance, and thermal and electrical barrier properties.

Printing Applications: Films are processed to be compatible with screen printing, offset printing and lithographic printing methods. Other coatings can be added to polyester to make it compatible with digital printing.

General Industrial Product: Polyester film, ideal for industrial or general purpose applications, including stencils.