PE film has moisture resistance and low moisture permeability. Polyethylene film (PE) can produce low-density, medium-density, high-density polyethylene and cross-linked polyethylene and other products with different properties according to different manufacturing methods and control methods.

Low-density polyethylene

Its density is about 0.92g/cm3. Low-density polyethylene film has good transparency and heat-sealability, and can be waterproof and moisture-proof; low tensile strength, high tensile elongation, and easy to wrinkle. For films below 0.03mm, the tension control should be small, and the tension should be Constant, especially when heated, it is more likely to be deformed, causing difficulty in color registration. Therefore, when drying, the surface temperature of the film should not be too high (within 55 degrees). According to the different film forming process, it can be divided into blown film (IPE), cast film (CPE), low foaming film and so on. The tensile strength and opening of IPE film are better than CPE film, and it can be used for food bags, clothing bags, etc. by front printing; CPE film has uniform thickness, better surface gloss, transparency and heat sealing than PE, and can be printed on both sides. But the production cost is high. The CPE film is mainly used as the inner layer of the composite bag and the packaging of cosmetics, pickles and cakes; the low-foaming film has good decorative properties, thick texture, and is not easy to be stretched and deformed.

medium density polyethylene

Its density is about 0.93~0.94g/cm3, and its performance is between high density and low density polyethylene.

High-density polyethylene

The density is 0.94-0.965g/cm3. The heat resistance and mechanical strength of high-density polyethylene film are better than that of low-density polyethylene film, and the tensile elongation is small. The film thickness is generally above 0.03mm, but the transparency is poor. With front printing, it is mainly used as vest bag, garbage bag and liner bag, etc.

XLPE

Because it has higher heat resistance, tensile strength, thermal shrinkage and barrier properties than other polyethylene products, its use is further expanded, and it is mostly used as heat shrinkable packaging film in 2014.

In general, as the density increases, the mechanical and barrier properties will increase accordingly, as will the heat resistance. Polyethylenes of the same density have different properties due to

metallized film Factory different film forming processes. This is because the drooling method can rapidly cool, low crystallinity, high transparency, and low turbidity, but the molecular arrangement tends to be more irregular, so the barrier property is small, that is, the transmittance is large, the elongation is low, and the tear resistance is low. Poor cracking.

Edit this section of the production process

The film blowing machine is a mechanical device that heats and melts PE plastic particles and blows them into a film. First, add the dried polyethylene particles into the lower hopper, and enter the screw from the hopper by the weight of the particles themselves. The plastic particles move forward. During the moving process, due to the friction between the plastic and the screw, the plastic and the barrel, the collision and friction between the particles, and the external heating of the barrel, it gradually melts. The molten plastic is removed from the impurity by the filter screen of the machine head and comes out from the die opening of the die head. After being inflated and cooled by the air ring, it is pressed by the herringbone plate, and the finished film is rolled by the traction roller into a tube.

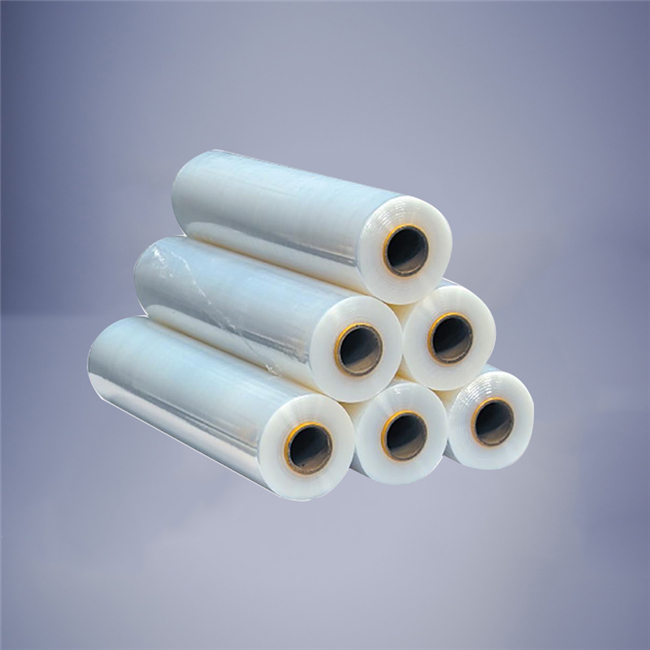

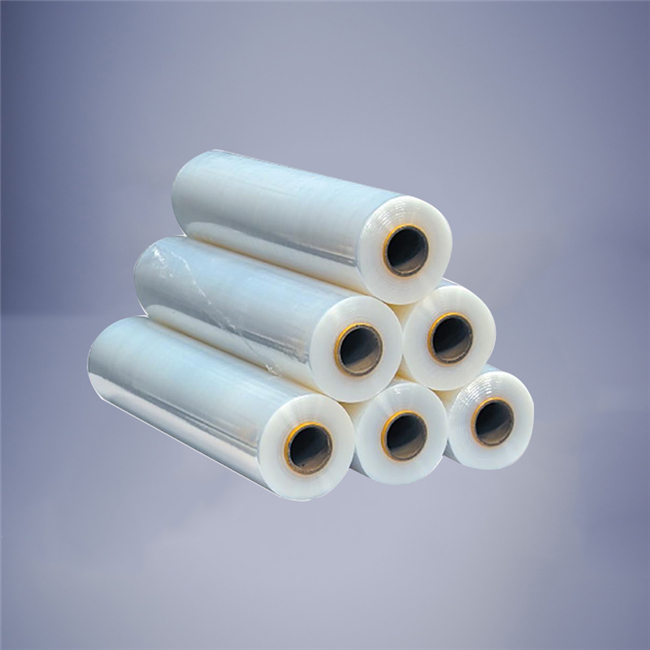

LDPE Film

product name: ldpe film

width: <=3m

thickness: 30-100μ

Material:LDPE Film

use: LDPE is mainly used for film products, such as agricultural film, ground covering film, agricultural film, vegetable Films, etc.; Packaging film such as candy, vegetables, frozen food packaging; Blow film for liquid packaging (milk,Soy sauce , juice. Tofu, soy milk); Heavy packing bag, shrink packaging film, elastic film, lining film; build Construction film, general industrial packaging film and food bags, etc.