Candy Twist Film

Material:Plastic Film

In the world of advanced technical textiles, few materials offer the multi-functional performance of Aluminum Foil Coated Fabric. Combining the lightweight flexibility of high-strength fabric with the reflective, conductive, and insulating properties of aluminum, this innovative composite material has become indispensable across industries ranging from aerospace and construction to firefighting and telecommunications.

Whether you're designing a thermal blanket for spacecraft, creating fire-resistant protective gear, or shielding sensitive electronics from electromagnetic interference (EMI), aluminum foil coated fabric delivers unmatched protection, durability, and efficiency. As global demand for energy-saving, heat-resistant, and EMI-shielding materials grows, this high-performance textile is emerging as a go-to solution for engineers, manufacturers, and safety professionals.

In this comprehensive, SEO-optimized article, we’ll explore what aluminum foil coated fabric is, how it’s made, its key benefits, real-world applications, and why it’s revolutionizing modern industrial and protective technologies.

What Is Aluminum Foil Coated Fabric?

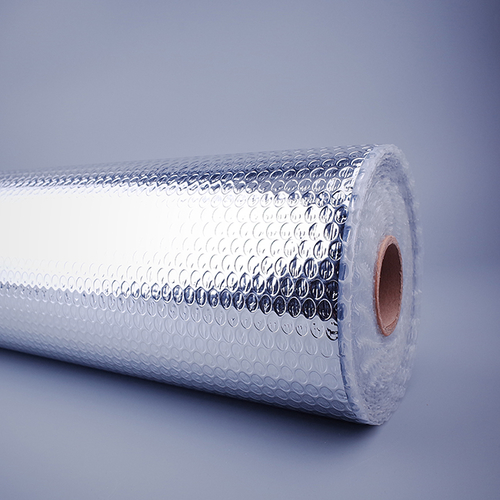

Aluminum foil coated fabric is a composite material created by laminating a thin layer of pure aluminum foil onto a high-performance textile substrate—typically made from fiberglass, polyester, aramid (such as Nomex or Kevlar), or nylon. The result is a flexible, lightweight, yet highly durable material that combines the mechanical strength of fabric with the thermal, electrical, and reflective properties of aluminum.

The aluminum layer is usually applied through precision lamination using heat, pressure, or adhesive bonding, ensuring a uniform, wrinkle-free coating that remains intact under bending, folding, and exposure to extreme conditions. Depending on the application, the fabric may be single-sided or double-sided coated, and can include additional treatments such as anti-corrosion layers, flame retardants, or conductive backings.

This hybrid material is engineered to reflect radiant heat, block electromagnetic waves, resist fire, and maintain structural integrity in harsh environments—making it far more versatile than standard insulation or shielding materials.

How Is Aluminum Foil Coated Fabric Made?

The manufacturing process involves several critical steps to ensure performance and reliability:

Base Fabric Selection: A high-tensile textile is chosen based on the intended use—fiberglass for high-temperature resistance, aramid for flame protection, or polyester for flexibility and cost-efficiency.

Surface Preparation: The fabric is cleaned and treated to enhance adhesion.

Aluminum Lamination: A thin (typically 10–50 microns) aluminum foil layer is bonded to the fabric using thermal or adhesive lamination techniques.

Protective Coating (Optional): A clear lacquer or silicone coating may be applied to prevent oxidation and improve durability.

Quality Testing: The final product is tested for peel strength, reflectivity, EMI shielding effectiveness, and thermal resistance.

The result is a seamless, flexible sheet that can be cut, sewn, or formed into complex shapes without compromising its protective properties.

Key Benefits of Aluminum Foil Coated Fabric

Superior Thermal Insulation

Aluminum is an excellent reflector of radiant heat. When used in insulation blankets, HVAC wraps, or industrial enclosures, the fabric reflects up to 95% of infrared radiation, significantly reducing heat transfer and energy loss.

Fire and Heat Resistance

When combined with fiberglass or aramid substrates, aluminum foil coated fabric can withstand temperatures exceeding 500°C (932°F), making it ideal for fire barriers, exhaust wraps, and protective clothing for firefighters and industrial workers.

EMI/RFI Shielding

The conductive aluminum layer acts as a Faraday cage, blocking electromagnetic and radio frequency interference. This is crucial for protecting sensitive electronics in medical devices, data centers, military equipment, and aerospace systems.

Lightweight and Flexible

Unlike rigid metal sheets or heavy insulation boards, this fabric remains pliable and easy to install around pipes, cables, or irregular surfaces—reducing labor costs and improving fit.

Moisture and UV Resistance

The aluminum layer provides a complete moisture barrier, preventing condensation, mold, and corrosion. It also resists UV degradation, making it suitable for outdoor applications.

Durability and Longevity

Resistant to tearing, abrasion, and chemical exposure, aluminum foil coated fabric maintains its performance over time, even in demanding environments.

Customizable Performance

Available in various thicknesses, weights, and backing materials, it can be tailored for specific thermal, electrical, or mechanical requirements.

Major Applications of Aluminum Foil Coated Fabric

1. Thermal Insulation Systems

Widely used in:

HVAC duct insulation

Industrial pipe and boiler wraps

Automotive exhaust heat shields

Refrigerated transport liners

Building insulation for roofs and walls

By reflecting heat instead of absorbing it, the fabric improves energy efficiency and reduces cooling or heating loads.

2. Fire Protection and Safety Gear

Used in:

Firefighter turnout gear and proximity suits

Welding blankets and spark guards

Foundry and kiln insulation

Emergency survival blankets (space blankets)

Its ability to reflect radiant heat protects personnel and equipment in high-risk environments.

3. EMI/RFI Shielding Solutions

Critical in:

Electronic enclosures and server racks

Military communication devices

Aerospace avionics

MRI room shielding

Smart home and IoT device housings

Helps prevent signal interference, data corruption, and equipment malfunction.

4. Aerospace and Automotive Industries

Used in:

Satellite thermal control blankets

Aircraft insulation layers

Electric vehicle battery enclosures

Turbocharger and exhaust wraps

Provides lightweight thermal management and EMI protection in compact, high-performance systems.

5. Construction and Architecture

Applied in:

Radiant barrier roofing underlayment

Energy-efficient curtain walls

Temporary emergency shelters

Green building insulation

Contributes to LEED certification and reduced energy consumption in buildings.

6. Packaging and Logistics

Used for:

Insulated shipping bags for pharmaceuticals and food

Temperature-controlled containers

Protective wrapping for sensitive equipment

Maintains internal temperature during transit without refrigeration.

Why Choose Aluminum Foil Coated Fabric Over Alternatives?

Compared to traditional materials like foam insulation, metal sheets, or vinyl-coated fabrics, aluminum foil coated fabric offers distinct advantages:

Higher Reflectivity than painted or metallized films

Better Flexibility than aluminum sheets or rigid panels

Superior EMI Shielding compared to conductive paints

Longer Lifespan than single-use foils or tapes

Easier Installation with minimal tools or adhesives

Its ability to combine multiple protective functions in a single layer makes it a cost-effective and space-saving solution.

Sustainability and Environmental Impact

As industries move toward greener solutions, aluminum foil coated fabric supports sustainability in several ways:

Energy Savings: Reduces heating and cooling demands in buildings and vehicles.

Recyclable Components: Aluminum and many base fabrics can be separated and recycled.

Extended Equipment Life: Protects machinery from heat and corrosion, reducing waste.

Reduced Carbon Footprint: Lower energy consumption translates to fewer emissions.

Manufacturers are also developing eco-friendly adhesives and bio-based fabric substrates to further improve environmental performance.

Care and Handling Tips

To maximize the lifespan and effectiveness of aluminum foil coated fabric:

Avoid sharp objects that can puncture the foil layer.

Clean with a damp cloth—do not use abrasive cleaners.

Store in a dry, cool place away from direct sunlight.

Do not crease or fold sharply, as this may crack the aluminum layer.

For EMI applications, ensure electrical continuity with grounding straps.

Proper handling ensures long-term performance in critical applications.

The Future of Aluminum Foil Coated Fabric

Innovation is driving the next generation of this material:

Smart Textiles: Integration with sensors for real-time temperature or EMI monitoring.

Self-Healing Coatings: Nanomaterials that repair minor surface damage.

Graphene-Enhanced Layers: For even higher conductivity and strength.

3D-Printed Composite Structures: Custom-shaped shields and insulators.

As technology advances, aluminum foil coated fabric will continue to play a vital role in energy efficiency, safety, and digital protection.

Conclusion

Aluminum foil coated fabric is not just another industrial material—it’s a high-performance, multi-functional solution that bridges the gap between insulation, protection, and innovation. From shielding satellites in space to protecting firefighters on the ground, its unique combination of thermal reflectivity, fire resistance, and EMI shielding makes it one of the most versatile textiles in modern engineering.

Whether you're designing energy-efficient buildings, manufacturing advanced electronics, or producing protective gear, aluminum foil coated fabric offers a smart, durable, and cost-effective answer to complex challenges.