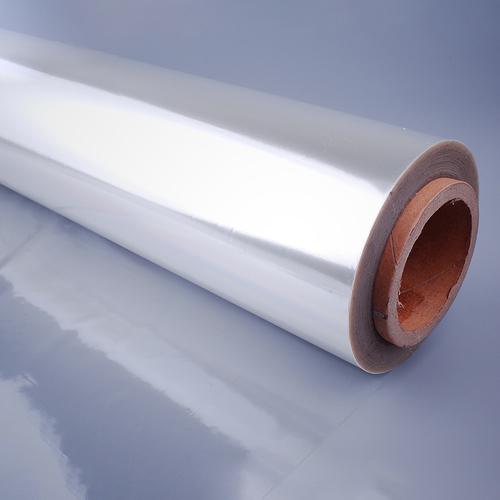

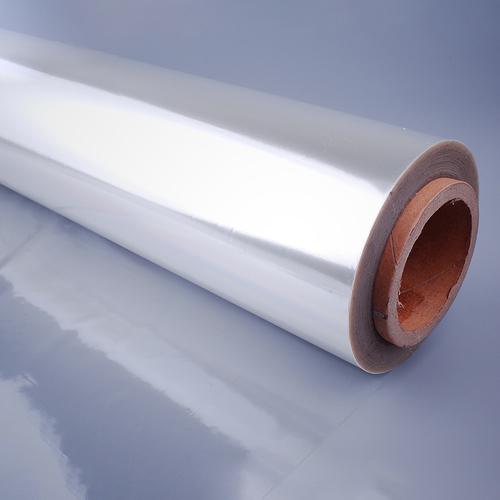

Plastic film is one of the most widely used and versatile materials in the world today. Found in everything from food packaging and agricultural coverings to medical supplies and industrial components, it plays a critical role in protecting, preserving, and enhancing products. But what exactly is plastic film, how is it made, and why is it so indispensable in modern life? In this article, we’ll explore its definition, manufacturing process, types, applications, advantages, and maintenance considerations.

1. What Is Plastic Film?

Plastic film is a thin, continuous polymeric material with a thickness generally under 0.25 mm (250 microns). It can be made from various polymers, such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polyvinyl chloride (PVC).

Unlike rigid plastics, plastic films are flexible, lightweight, and can be transparent or opaque. They are often used for packaging, wrapping, laminating, insulating, and covering surfaces.

2. How Is Plastic Film Made?

The production of plastic film typically follows these steps:

- Polymer Preparation – Base polymers are selected depending on the desired mechanical and chemical properties.

- Extrusion – The polymer is melted and forced through a flat die or blown through a circular die to create a thin sheet (blown film extrusion).

- Cooling and Solidifying – The hot film is cooled rapidly using air or water.

- Orientation (Optional) – The film is stretched in one or both directions to improve strength and clarity.

- Finishing – Films may be coated, printed, or laminated with other materials for added functionality.

- Winding and Cutting – The finished film is rolled and cut into the desired width and length for packaging or industrial use.

3. Types of Plastic Film

| Type of Film |

Main Polymer |

Key Properties |

Common Uses |

| Polyethylene (PE) |

LDPE, HDPE, LLDPE |

Flexible, moisture-resistant, transparent |

Food packaging, bags, shrink wrap |

| Polypropylene (PP) |

PP |

High clarity, heat resistance, stiffness |

Snack packaging, labels, tapes |

| Polyethylene Terephthalate (PET) |

PET |

Strong, high barrier, glossy |

Beverage labels, laminated pouches |

| Polyvinyl Chloride (PVC) |

PVC |

Transparent, strong, chemical-resistant |

Cling film, labels, shrink sleeves |

| Biodegradable Films |

PLA, starch blends |

Eco-friendly, compostable |

Sustainable packaging, produce bags |

| Barrier Films |

Multi-layer composites |

High oxygen/moisture barrier |

Coffee packaging, medical pouches |

4. Key Features and Advantages

- Lightweight – Reduces shipping costs and makes handling easy.

- Durable – Resistant to tearing, punctures, and moisture.

- Customizable – Available in various thicknesses, colors, and finishes.

- Printable – Supports high-quality printing for branding and labeling.

- Barrier Properties – Protects contents from oxygen, moisture, and light.

- Cost-Effective – Lower manufacturing costs compared to many alternatives.

- Versatile – Used in packaging, agriculture, construction, healthcare, and more.

5. Applications of Plastic Film

- Packaging Industry – Plastic film is the backbone of flexible packaging for food, beverages, pharmaceuticals, and consumer goods.

- Agriculture – Used in greenhouse covers, mulch films, and silage wrap to control temperature, moisture, and weed growth.

- Medical Sector – Films are used in sterile packaging for surgical instruments, IV bags, and diagnostic kits.

- Construction – Vapor barriers, protective wraps, and insulation layers rely on durable films.

- Electronics – Used for insulation, flexible circuits, and protective screens.

- Printing and Graphics – Films are laminated over prints for durability and visual enhancement.

- Household Use – Cling films, garbage bags, and freezer wraps are everyday examples.

6. How to Choose the Right Plastic Film

- Application Requirements – Consider mechanical strength, flexibility, and transparency.

- Barrier Needs – Determine whether protection from oxygen, moisture, or UV light is needed.

- Environmental Impact – Evaluate biodegradable or recyclable film options.

- Printing and Branding – Select films with good ink adhesion for graphics.

- Regulatory Compliance – For food or medical use, ensure compliance with FDA or EU regulations.

- Cost and Availability – Balance performance with budget and supply chain stability.

7. Environmental Considerations

Plastic films have been criticized for contributing to environmental pollution. However, modern innovations are addressing this:

- Recyclable Films – Single-polymer films that can be processed into new materials.

- Biodegradable Alternatives – PLA and starch-based films decompose under composting conditions.

- Lightweight Design – Reducing material use while maintaining strength lowers environmental impact.

- Closed-Loop Systems – Industrial recycling programs recover and reuse film waste.

8. Maintenance and Storage Tips

- Keep Dry – Store films in low-humidity conditions to prevent moisture damage.

- Avoid UV Exposure – Prolonged sunlight can degrade certain films.

- Handle Gently – Prevent creases and scratches during transport and handling.

- Use Before Expiry – Some specialty films (e.g., biodegradable) have limited shelf life.

- Protect from Heat – High temperatures can warp or melt films before use.

9. Benefits of Using Plastic Film

- Protects Products from moisture, dust, and contaminants.

- Extends Shelf Life of perishable goods.

- Improves Branding with high-quality printing and finishes.

- Reduces Costs in packaging, shipping, and storage.

- Enables Innovation in packaging design and product presentation.

10. Conclusion

Plastic film is a vital material in countless industries thanks to its lightweight, durable, and versatile properties. From food packaging and agricultural protection to medical applications and industrial uses, it offers unmatched flexibility in design and performance.

While environmental concerns remain, the rise of recyclable and biodegradable films shows that innovation is steering plastic film toward a more sustainable future. By choosing the right film type, thickness, and finish, businesses can protect their products, enhance their brand, and reduce waste—all while meeting the demands of modern markets.