Candy Twist Film

Material:Plastic Film

With the global energy shortage and the increase of environmental awareness, energy conservation and emission reduction have become important issues in various industries such as construction, industry and transportation. Among many energy-saving technologies, heat insulation materials are widely used in building exterior walls, pipelines, equipment and vehicles due to their good thermal insulation performance.

Definition and function of thermal insulation materials

Thermal insulation materials refer to materials that can effectively prevent heat conduction, convection or radiation, thereby reducing energy loss. This type of material achieves the purpose of heat preservation and energy saving by reducing the exchange of heat between different environments. Thermal insulation materials show different thermal insulation properties under different temperature environments, and their effects are usually measured by thermal conductivity (W/m·K). The smaller the thermal conductivity, the better the thermal insulation performance.

Common types of thermal insulation materials

Inorganic thermal insulation materials

Inorganic thermal insulation materials are usually non-flammable, high temperature resistant and chemically stable, and are often used in industrial and high temperature environments. Representative materials include:

Mineral wool (such as rock wool, glass wool): has good thermal insulation and sound absorption effects, and is widely used in building exterior walls and roofs.

Aluminum silicate fiber: excellent high temperature resistance, mostly used for high temperature pipes and furnace insulation.

Aerogel: known as the lightest solid in the world, with extremely low thermal conductivity, but high cost.

Organic insulation materials

Organic insulation materials are mostly based on polymers, light weight and easy to construct. Common ones are:

Polyurethane foam: good insulation effect, widely used in cold storage, refrigerated trucks, construction and other fields.

Polystyrene foam (EPS, XPS): rigid foam board, often used for wall and floor insulation.

Phenolic foam: has both fireproof and heat insulation properties, suitable for projects with high fire protection requirements.

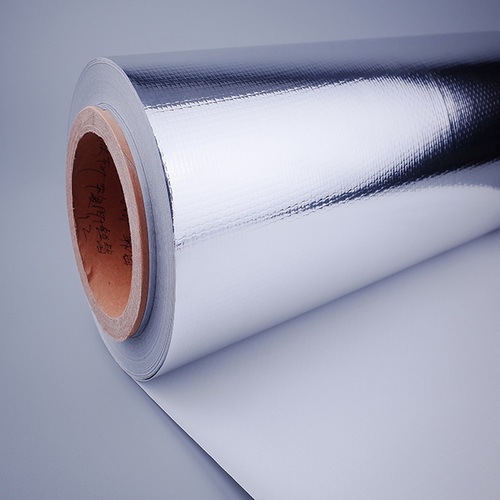

Composite insulation materials

In order to combine the advantages of different materials, there are also a variety of composite insulation boards on the market, such as composite insulation boards coated with reflective layers and combined with waterproof materials. These materials have relatively balanced insulation, waterproof and fireproof properties.

Application scenarios

Insulation materials are widely used in many fields:

Construction industry: a large amount of insulation materials are required in exterior wall insulation, roof insulation, and floor heating systems. The use of thermal insulation materials can not only significantly reduce energy consumption, but also improve indoor comfort.

Industrial field: Pipelines, boilers, chemical equipment, storage tanks, etc. require thermal insulation materials to prevent heat loss or protect the safety of operators.

Transportation: Refrigerated trucks, EMUs, aircraft, ships, etc. all use thermal insulation materials to improve energy utilization and passenger comfort.

New energy equipment: such as solar water heaters, heat storage systems, etc. also rely on high-efficiency thermal insulation materials to improve thermal energy utilization.

Development trends and prospects

At present, thermal insulation materials are developing in the following directions:

High performance: Develop thermal insulation materials with lower thermal conductivity and thinner thickness, such as nano thermal insulation materials, aerogels, etc., to meet the needs of energy-saving buildings and high-end equipment.

Green and environmental protection: Promote thermal insulation materials made of renewable resources to reduce carbon emissions during production and use.

Multifunctional integration: Thermal insulation materials are being combined with waterproof, fire-resistant, sound-absorbing and other functions to improve comprehensive performance and simplify construction processes.

Intelligent application: With the development of intelligent buildings, new products such as adjustable insulation materials and phase change energy storage insulation materials are gradually entering the market.

As an important supporting technology for energy conservation and consumption reduction, insulation materials are being widely used and continuously innovated in all walks of life. In the future, with the development of materials science and manufacturing technology, a new generation of efficient, environmentally friendly and intelligent insulation materials will make greater contributions to the sustainable use of global energy and green development. Choosing the right insulation material is not only related to the quality of the project and the safety of use, but also an important way to promote energy conservation and emission reduction.