Candy Twist Film

Material:Plastic Film

In the fields of industry, construction, home, etc., the choice of insulation materials is directly related to energy consumption, comfort and long-term economic benefits. With the increasing awareness of energy conservation and environmental protection, a variety of insulation materials have emerged in the market, including traditional glass wool, rock wool, polyurethane foam, as well as emerging aerogels, reflective films, etc.

1. What is insulation efficiency?

The core indicator of insulation efficiency is thermal conductivity (Thermal Conductivity), which is expressed in W/(m·K). The lower the thermal conductivity, the weaker the heat transfer ability of the material and the better the insulation effect. Generally speaking, materials with a thermal conductivity of less than 0.06 W/(m·K) can be considered to have good insulation performance.

2. Detailed performance analysis

1. Glass wool and rock wool

These two materials are traditional mineral fiber insulation materials with good thermal insulation effect, flame retardant and non-combustible, and affordable prices. Glass wool is lighter and suitable for large-area laying; rock wool has stronger high temperature resistance and is suitable for industrial scenes with higher fire protection requirements.

Suitable for: Residential or ordinary industrial buildings that focus on cost-effectiveness and do not require high thickness.

2. Polyurethane foam (PU)

Polyurethane foam is a highly efficient thermal insulation material with extremely low thermal conductivity and good moisture resistance. Its closed cell structure makes it the preferred material for refrigeration, cold chain transportation, and thermal insulation walls.

Suitable for: Cold storage, refrigerators, or exterior wall insulation systems that require extremely high thermal insulation performance and are in a humid environment.

3. Extruded polystyrene (XPS)

XPS combines strength and thermal insulation performance and is widely used in building foundations, floors, roofs, etc. Its water absorption rate is much lower than that of glass wool and rock wool, and it is more suitable for long-term humid environments.

Suitable for: Foundation insulation, geothermal systems, and building exterior envelope structures.

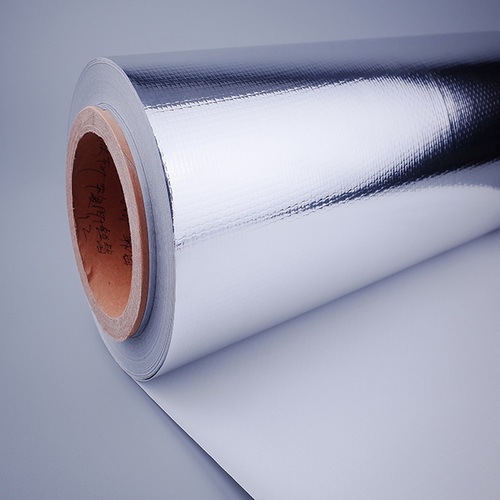

4. Reflective film materials

This type of material does not achieve thermal insulation by reducing heat conduction, but achieves cooling effect by reflecting solar radiation heat. It is commonly found in roofs, carports, warehouses and other spaces.

Suitable for: Metal roofs, summer sun protection, garages and other high-radiation environments.

5. Aerogel

Aerogel is one of the insulation materials with the lowest thermal conductivity. It can achieve excellent thermal insulation effect with extremely thin thickness and is widely used in high-end fields such as aerospace, military industry, and special equipment.

Suitable for: High-end engineering or precision equipment with limited space and extremely high requirements for thermal insulation efficiency.

The difference in efficiency of different insulation materials mainly comes from their structure, density, composition and use direction. When selecting materials, you can't just look at thermal conductivity, but also consider factors such as the actual application environment, humidity, construction convenience and budget.

Recommended material selection suggestions are as follows:

Residential exterior wall/roof insulation: polyurethane or extruded board + reflective film, double insulation;

Industrial equipment/high-temperature pipelines: rock wool or aerogel, both heat-insulating and flame-retardant;

Home decoration with limited budget: glass wool is cost-effective and suitable for ceiling insulation;

Refrigerated transportation/cold storage construction: polyurethane foam material is preferred;

High-tech field/precision insulation: aerogel material is preferred.

Insulation efficiency is not only related to energy saving and consumption reduction, but also affects the comfort and safety of living and working environments. Only by understanding the performance differences of various insulation materials can we make the most suitable decision for our own needs among various choices. Under the future low-carbon and environmental protection trend, the selection of efficient and sustainable insulation materials will become an important direction for architectural and industrial design.