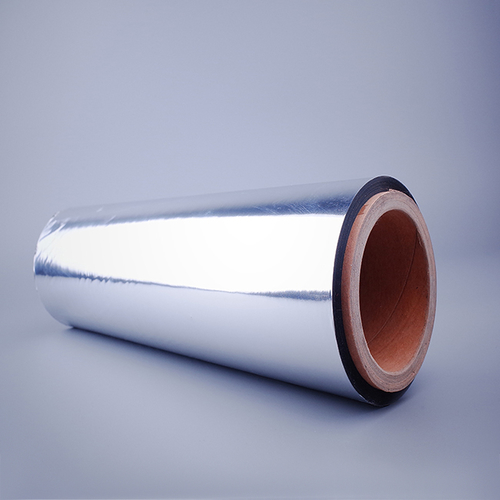

Candy Twist Film

Material:Plastic Film

Laminating film is widely used in printing and packaging, document protection, label making and other industries. It not only enhances the wear resistance, water resistance and aesthetics of paper, but also prolongs the service life of printed products. However, during the laminating process, many users will encounter a headache: bubbles or wrinkles after laminating.

1. Common causes of bubbles in laminating film

Improper temperature setting

Thermal laminating film usually needs to be operated at a certain temperature (such as 90℃~130℃). If the temperature is too low, the bonding is insufficient, which will cause bubbles in local areas; while too high a temperature may cause excessive volatilization of the adhesive and form gaps.

Laminating speed does not match

When the machine runs too fast, the glue layer does not have time to be evenly heated, the bonding effect is not ideal, and bubbles are easily formed. On the contrary, too slow may cause the paper to bend and affect the flatness.

The paper surface is uneven or contains dust

If there is dust, oil stains or particles on the surface of the printed matter, the film cannot fit the paper completely, and bubbles will naturally appear. Especially in an environment with high static electricity, it is easier to absorb dust.

Film quality problems

Poor quality laminating films may have problems with uneven distribution of the adhesive layer and different thicknesses, which will directly affect the lamination quality after lamination.

2. Common causes of wrinkles in laminating films

Improper tension control

The tension of the upper and lower rollers of the laminating machine is inconsistent, which will cause the film to deviate and fold during the laminating process, forming wrinkles.

The paper is not completely dry

If the printed matter is not completely dry before laminating, the water content of the paper is too high, and it will deform after being heated, which will cause wrinkles.

Excessive temperature or uneven pressure

Excessive temperature will soften the film, and the film will easily be pulled and wrinkled when the tension increases; at the same time, if the pressure of the laminating roller is uneven, it will also cause local wrinkles.

Poor equipment adjustment

Mechanical failures such as roller asynchrony, bearing wear, and improper film movement are also common factors that cause wrinkles.

3. Effective solutions

Reasonable setting of temperature and speed

According to different types of laminating films (such as PET, BOPP, etc.), adjust the appropriate temperature and running speed. It is recommended to do a small batch test first to ensure that the parameters match.

Keep the environment clean and the paper dry

Use a dust collector or fan to remove dust from the surface of the printed matter before laminating to ensure that the paper is completely dry and flat.

Choose high-quality laminating film materials

Using laminating films with stable quality and uniform glue layer can greatly reduce the chance of bubbling and wrinkles and improve the quality of the finished product.